Why does In a combined cycle power plant, the bypass stack is typically larger in diameter than the main stack

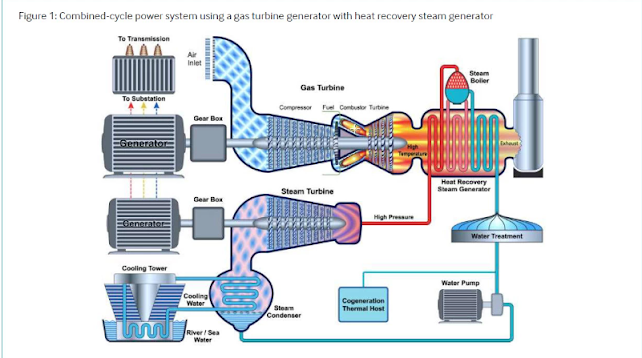

In a combined cycle power plant, the bypass stack is typically larger in diameter than the main stack for several reasons:

For stack need, pls contact: ybchimney@gmail.com www.industrychimney.net

- Flow requirements: The bypass stack needs to handle a larger volume of exhaust gases than the main stack, as it is designed to bypass the heat recovery steam generator (HRSG) during startup, shutdown, and low-load operation. During these periods, the exhaust gases from the gas turbine bypass the HRSG and are discharged directly to the atmosphere through the bypass stack. Therefore, the bypass stack needs to have a larger diameter to accommodate the higher flow rate of exhaust gases.

- Pressure drop: The bypass stack needs to maintain a lower pressure drop than the main stack to prevent the gas turbine from experiencing excessive back pressure during startup, shutdown, and low-load operation. A larger diameter bypass stack can reduce the pressure drop by allowing the exhaust gases to flow more freely.

- Noise reduction: The bypass stack is often designed with noise reduction features, such as silencers or diffusers, to reduce the noise generated by the gas turbine during operation. A larger diameter bypass stack can accommodate larger noise reduction devices, which can further reduce the noise level.

Overall, the larger diameter of the bypass stack allows it to handle the higher flow rate of exhaust gases while maintaining a lower pressure drop and reducing noise levels.

评论

发表评论